HireSmart Cares Grant Brings Industrial Laser Cutter to Empower College and Career Center

Local machine shops have a problem: they can’t find enough workers who know CNC plasma cutters and laser cutting technology. Jackson County’s Empower College and Career Center has a solution.

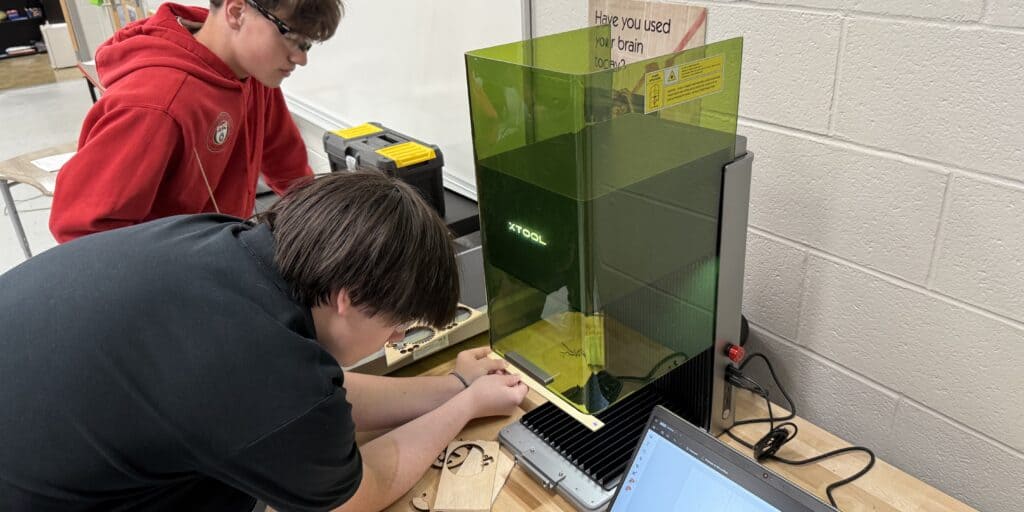

Thanks to a $4,439 grant from HireSmart Cares, students in Don Loggins’ mechatronics program are now working with a commercial-grade laser cutter that cuts metal, wood, and plastics — preparing them for good-paying jobs that don’t require a four-year degree.

Thanks to a $4,439 grant from HireSmart Cares, students in Don Loggins’ mechatronics program are now working with a commercial-grade laser cutter that cuts metal, wood, and plastics — preparing them for good-paying jobs that don’t require a four-year degree.

“This is getting them familiar with using software that they may see out in the field,” said Loggins, who teaches Advanced Technology, Engineering & Mechatronics at Empower. “It’s just going to be at a different scale, much bigger in real life.”

Beyond the Craft Stick Classroom

In Loggins’ lab, 68-75 students per semester work on projects that range from building roller coasters to constructing Rube Goldberg machines. But until now, students faced limitations when it came to manufacturing the parts they designed.

“During one project (last year), students were tasked with designing an electric toy car,” Loggins explained in his grant application. “For some of the parts, students designed 3D printed things like gears for the car’s transmission. For other parts of the car, students used craft sticks that were cut to make various other parts for their respective car.”

The new xTool F1 Ultra laser cutter changes that equation entirely.

“If students (last year) had access to the F1 Ultra, they could have cut the parts from a sheet of acrylic or even metal to make the part in less than a couple minutes once designed,” said Loggins.

Now, thanks to the grant, students can utilize a machine that cuts through materials up to 18 millimeters thick, including wood, plastics, and thin metals, giving them hands-on experience with equipment they’ll encounter in modern manufacturing facilities.

Student Perspective: Hands-On Learning

For junior Jake Dyer, the new laser cutter represents a significant opportunity.

“It’s such a cool piece of technology and something that most schools won’t have, and it allows me to kind of get a step up where other people in the field may not have experience,” he said.

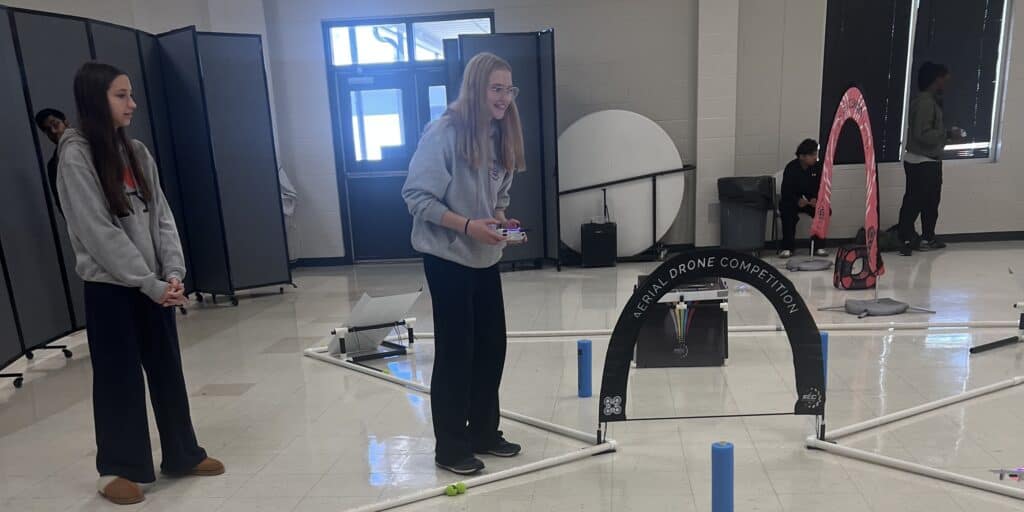

Dyer is also part of a small group building drones from scratch, another HireSmart Cares-funded initiative that demonstrates the comprehensive nature of hands-on learning in the program.

“It’s definitely been a challenge,” said Dyer of the drone building. “It’s definitely been time consuming, because there’s not a whole lot on how to build it. But it’s great to see something that I’ve created myself working.”

Real Results: From Classroom to Career

That industry connection has already paid dividends. Through partnerships with companies like Michelin, Loggins has seen students land positions that offer both immediate employment and long-term career growth.

Take Theron Odell. He was the quiet kid who sat in the back of Loggins’ class. Today, at 18 years old he’s a participating in Michelin’s Scholar Program while completing his electrical engineering degree at Lanier Technical College.

The Michelin Scholar Program covers all educational costs beyond what Georgia’s HOPE scholarship provides, offers part-time work at $23 per hour, and guarantees full-time positions upon graduation with salaries that can touch the $70,000 range.

For Loggins, seeing students like Theron succeed validates the importance of hands-on technical education in an era when college pathways dominate career guidance.

“You see them grow from this quiet, shy individual sitting in the back of the room, and now they are transitioning into a productive member of society,” Loggins said. “Teaching is one of those professions where you don’t see the payoffs right off the bat. But the potential is there. Kids want those opportunities, and I like to see the ones that surprise you.”

The Bigger Picture

The equipment grant represents HireSmart Cares’ broader mission of helping students develop job-ready skil

ls while avoiding crushing college debt. For many students, traditional four-year degrees lead to significant financial burdens without guaranteeing career success.

The lab serves as a bridge between academic learning and real-world application. Students master CAD design, precision measurement, understanding tolerance and fit, manufacturing processes, and resource management — skills that translate directly to high-paying careers in modern manufacturing.

Expanding Opportunities

The laser cutter will serve multiple functions beyond individual projects. Loggins plans to use it to help Technology Student Association (TSA) members create items for the school store, allowing them to self-fund supplies and competition registrations as the program expands.

The equipment will benefit not just current students but serve multiple classes for years to come, maximizing the impact of HireSmart’s investment in the next generation’s technical education.

Changing Perceptions

As students like Theron Odell demonstrate, those moments of pride translate into life-changing opportunities, proving that the path from high school to high-paying career doesn’t always require a traditional college degree, just the right tools, training, and dedication to learning practical skills that employers desperately need.

HireSmart Cares is a 501(c)(3) nonprofit organization focused on helping students develop career-ready skills through grants, scholarships, and workforce development initiatives. To learn more about HireSmart Cares, visit hiresmartcares.org. Educators with innovative approaches to preparing students for industry-relevant skills can apply for a HireSmart Cares grant at hiresmartcares.org/ideas-application.